Seibou Chemical

Shandong Seibou Chemical Technology Co., Ltd., located in Zibo High-tech Development Zone, Shandong, is a professional manufacturer of R&D and production of alumina series polishing powder and aluminum hydroxide flame retardant series products. The company system is composed of planning department, business department, production department, quality inspection department, laboratory, finance department and storage department.

Marketing market

The company has introduced domestic and foreign high-tech, advanced complete sets of production equipment and technological process to produce higher quality products. Recruit domestic professionals who have long been engaged in research and development, production, quality inspection, and management in this industry, and provide professional training for all employees to ensure that product quality meets all elements of international similar products under absolute control.

Application field

Seibou Chemical can provide a wide variety of products. According to different technical requirements, different quality level requirements and technical reform support customized by customers, in the fields of alumina polishing and grinding powder and various hydroxide flame retardants, Seibou Chemical is Customers are offered a variety of options and opportunities.

Marketing market

Based on the business tenet of customer first, quality assurance, and integrity, the company revolves around the enterprise spirit of pioneering, innovative, enterprising, efficient, and reputation-based, with full enthusiasm, sincere cooperation attitude, and win-win business philosophy, warmly welcome customers at home and abroad Friends and companies from all walks of life come to visit us!

PRODUCT

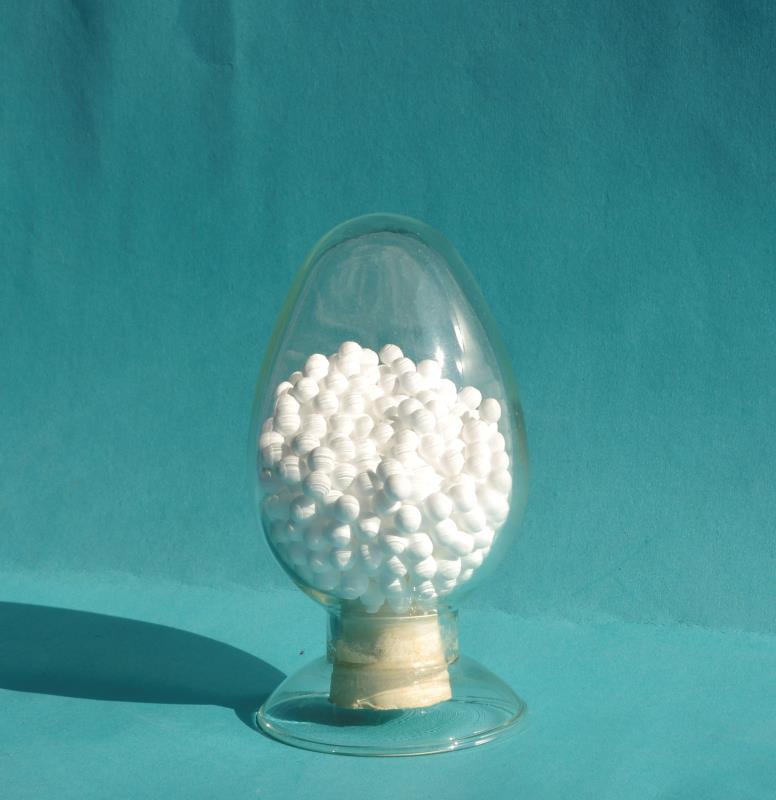

Aluminium Hydroxide

Aluminium Oxide

Catalyst

这里是标题一h1占位文字

信息为测试元素,使用时候可删除该元素放置自己想放的元素

信息为测试元素,使用时候可删除该元素放置自己想放的元素

这里是占位文字

信息为测试元素,使用时候可删除该元素放置自己想放的元素

NEWS